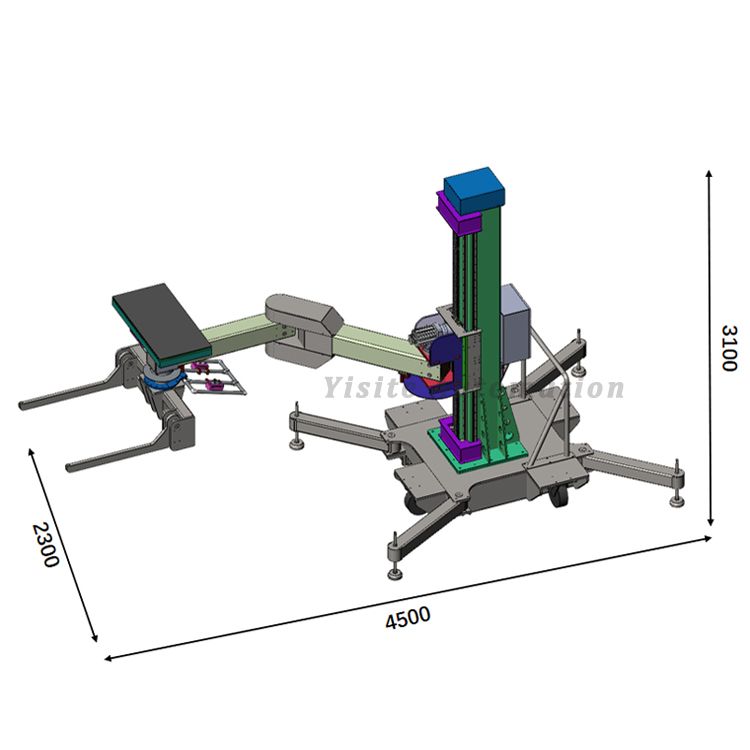

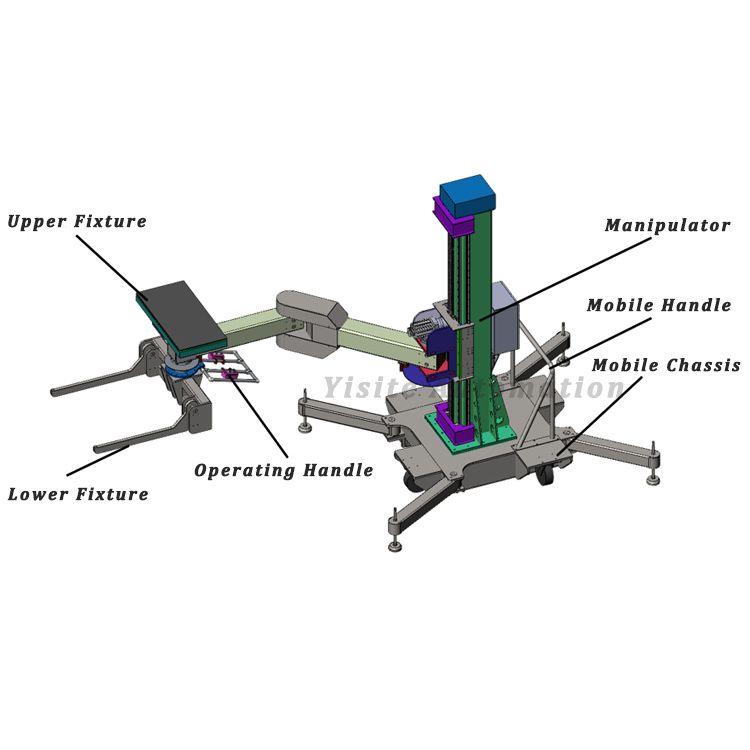

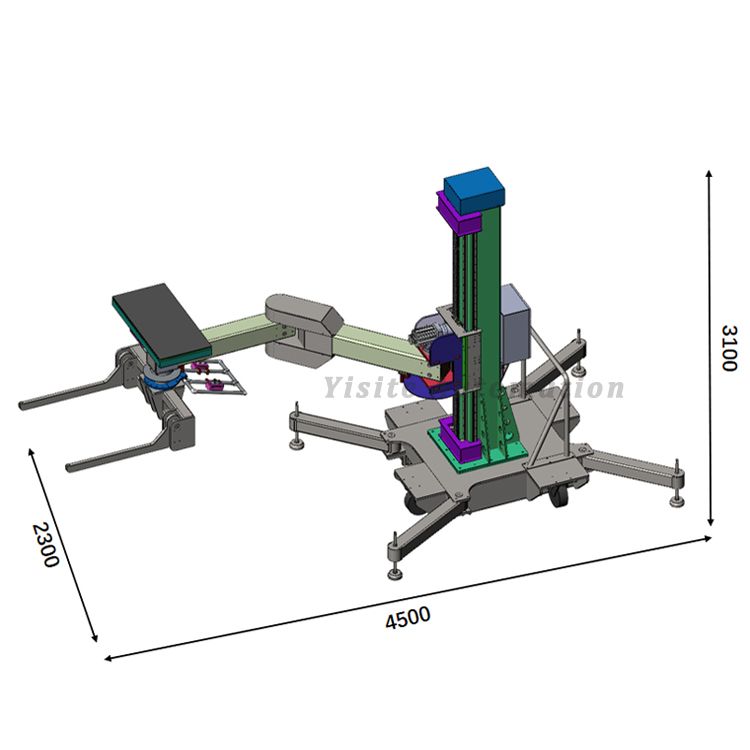

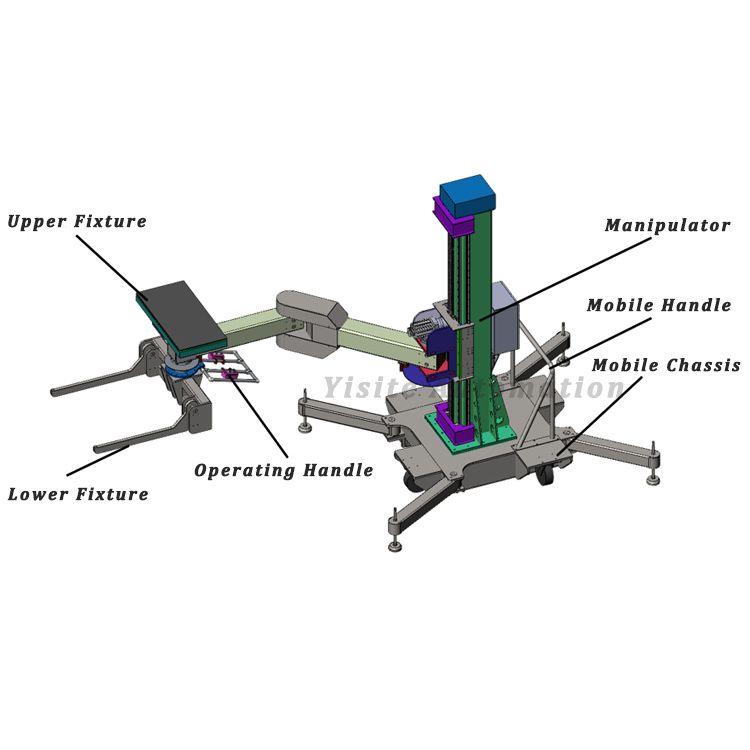

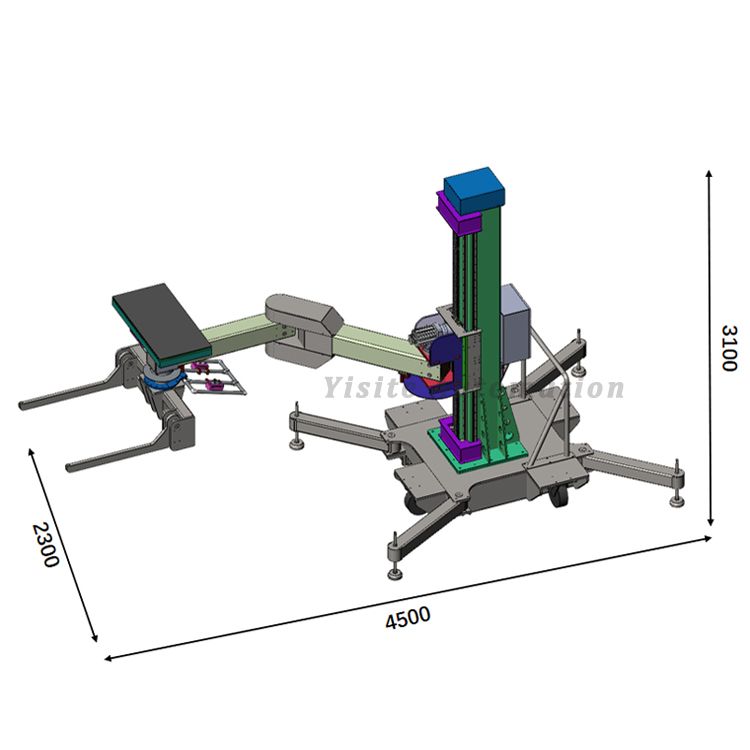

The hard-arm power-assisted manipulator consists of a balancing host, a grabbing fixture, and an installation structure. It can balance various weights from 20 to 300kg and is suitable for material transfer operations.

The characteristics of full balance and smooth movement allow the operator to easily carry out workpiece handling, positioning, assembly and other operations. It has high stability, simple operation, high efficiency, high safety performance, and is equipped with a gas cutoff protection device. The main components are all made of internationally renowned brands, and the quality is guaranteed.

It has a full suspension function and is easy to operate; manufactured according to ergonomic principles, it is comfortable and convenient to operate; the structural design is modular and the air circuit control is integrated; labor costs are reduced by 50%, labor intensity is reduced by 85%, and production efficiency is increased by 50%; according to the load and stroke,they are customized and come in various forms to meet different needs.

Scope of application of power-assisted manipulators: widely used in warehouse loading and unloading in the automotive industry, chemical industry, product packaging, electrical appliance industry, ceramic sanitary ware industry, building materials and furniture industry, metal parts, machinery manufacturing and processing, repetitive high-frequency handling work, natural gas and petroleum energy Industry, new energy battery, automated logistics and other industries, equipped with different grippers, it can realize the handling and palletizing of products of various shapes in different industries.

about us

We are a professional customized automation equipment manufacturer. Our products include depalletizer, pick and place packing machine, palletizer, robot integration application, loading and unloading manipulators, carton forming,carton sealing,pallet dispensper,wrapping machine and other automation solutions for back-end packaging production line.

Our factory area is about 3,500 square meters. The core technical team has an average of 5-10 years of experience in mechanical automation, including 2 mechanical design engineers. 1 programming engineer, 8 assembly workers, 4 after-sales debugging person, and other 10 workers

Our principle is “customer first, quality first, reputation first”, we always help our customers “increase production capacity, reduce costs, and improve quality” we strive to become a top supplier in the machinery automation industry.