Products

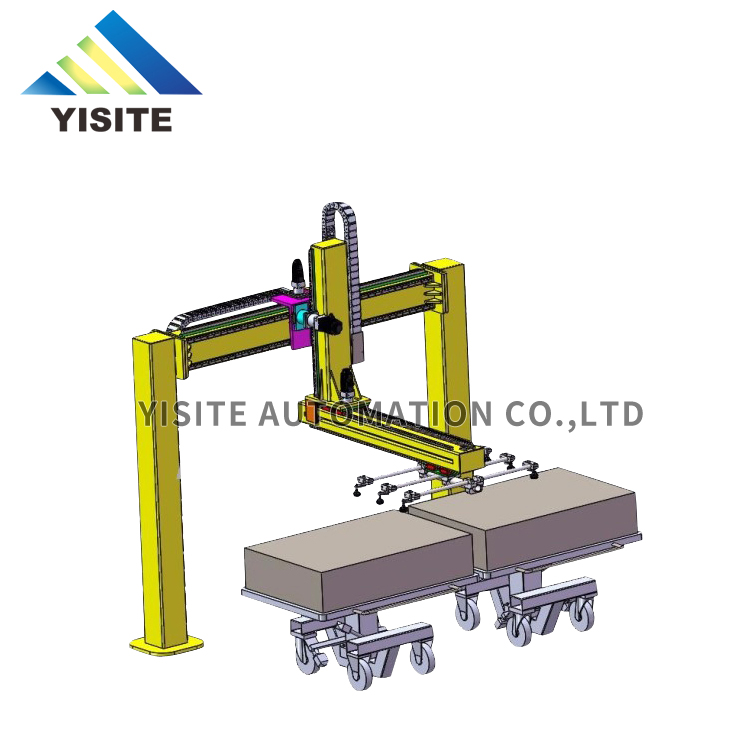

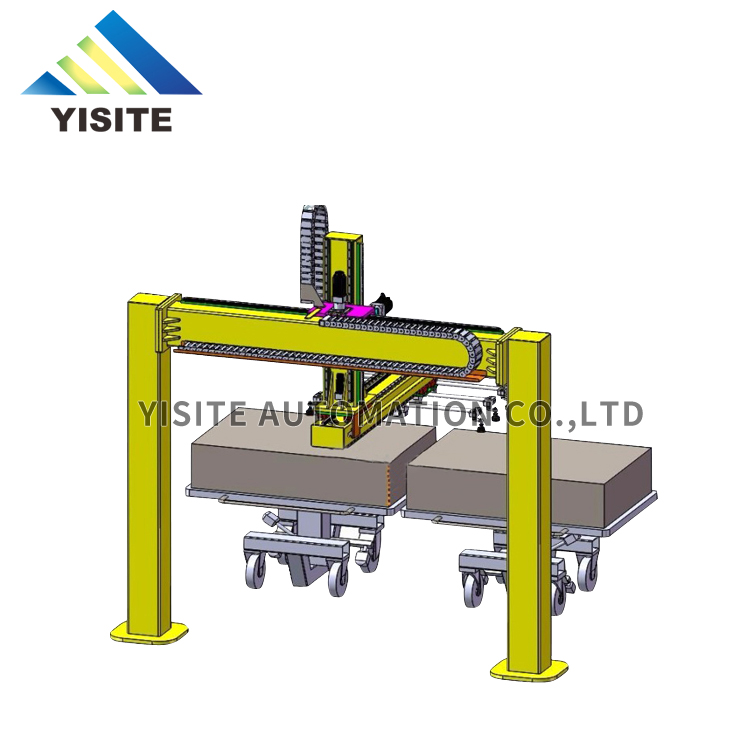

Two column stacking palletizer

| Item | Value |

| Applicable Industries | Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other |

| After Warranty Service | Video technical support, Online support, Spare parts |

| Local Service Location | None |

| Showroom Location | None |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | Hot Product 2020 industrial pneumatic manipualtor |

| Warranty of core components | 1 Year |

| Core Components | Main pneumatic components ,and gripper for different load item |

| Condition | New |

| Place of Origin | Dongguan,China |

| Brand Name | YISITE |

| Dimension(L*W*H) | 3500 Hx3000mm Lx800mm W |

| Warranty | 1 Year |

| After-sales Service Provided | Video technical support,online technical support |

| Load capacity | 50kg/80kg/150kg/200kg/300kg/500kg |

| Industrial pneumatic manipulator | Customize Max 500kg |

| Customized Services | yes |

| lifting height | 0-1700mm,1700mm-2500mm or customize |

| Application | industrial pneumatic manipulator material handling equipment for lifting paper roll ,PE film roll ,wheel hub, machinery parts ,tyre,sanitary parts ,car seat ,films roll ,coil ,leaf spring ect ,could customize the gripper for different heavy load item ,China robot mobile zero gravity crane gantry handling tire wheel hub car manipulator |

| Function | 360 degree rotation ,up and down function ,,90 degree flip function ,Full balancing ,floating ,and Explosion-proof: suitable for working in special environments,Low-voltage alarm device,Load-bearing limit protection system ,Misuse of protective system ,Gas shutoff protection,Brake device,Pressurization device,one button operation ,rear wheel cap hub car door instrument panel dash board manipulator |

| Product name | rear wheel cap hub car door instrument panel dash board manipulator

industrial pneumatic manipulator for lifting machinery parts ,leaf spring ,tyre, car seat ,sanitary parts ,wheel hub and paper rolls ,film roll or another roll material ,could customize ,welcome inquiry ,China robot mobile zero gravity crane gantry handling tire wheel hub car manipulator |

| working | connected to compressed air and then work,no need electricity |

| air pressure | 0.6-0.8mpa |

| Max loading | 500KG |

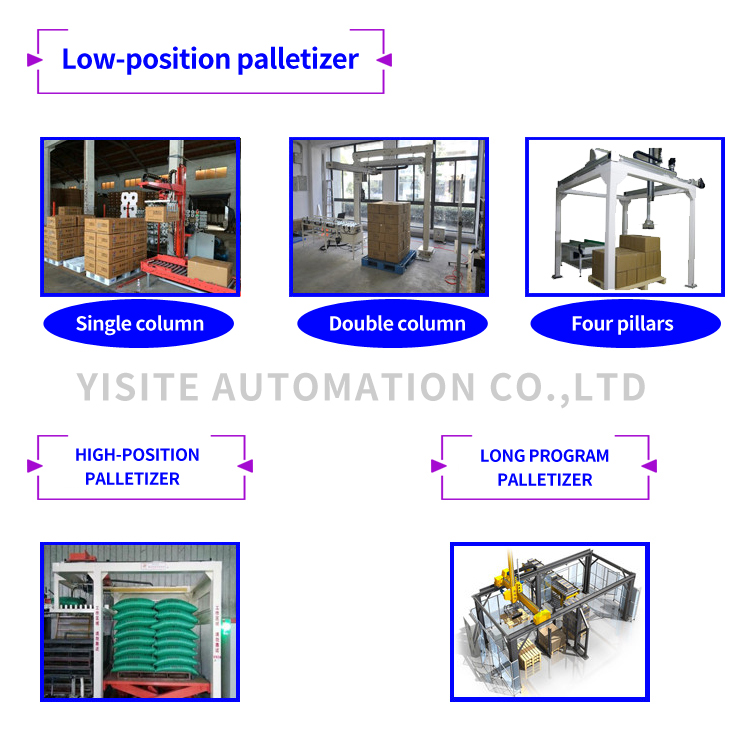

Double column palletizer structure

Double column palletizer is an automatic handling palletizing equipment, replacing manual handling and palletizing, production can quickly improve the company's production efficiency and output, while reducing the errors caused by manual handling. Column robot palletizer is an organic combination of machinery and computer program, which can save labor and space. It also has the characteristics of flexible operation, high stability and high operational efficiency. At present, the production application of column robots has penetrated into all aspects of product production to achieve product processing, pick and place, handling and stacking within the established procedures and scope.

Advantages of double column palletizer

1. The price of column palletizer is affordable, which is the salary of two or three loaders for one year.

2. The column palletizer adopts full servo drive, with accurate movement and works 300-600 times per hour, which fully meets the output demand of most enterprises.

3. The column palletizer is well configured and well selected.

4. The structure of column palletiser is simple and reasonable, easy to operate and maintain, and can be applied to multiple production lines at the same time.

5. The column palletizer can choose single claw hand and double gripper, and the gripper, adsorption or plywood gripper can be changed according to the product type, which can palletize bags, boxes, barrels and other materials.

6. The column palletizer has small footprint, flexible movement, high operation precision, large working range, and a control system to ensure the operation precision.

7. The comprehensive application cost of the column palletizer is low, and it can achieve cost utilization, and because the main components of spare parts are few, the maintenance cost is low, the power consumption is low, the failure rate is low, and the maintenance is easy.

8. The palletizing type and the number of palletizing layers can be set arbitrarily, and the pallets are neat and will not collapse, which is convenient for storage and transportation.