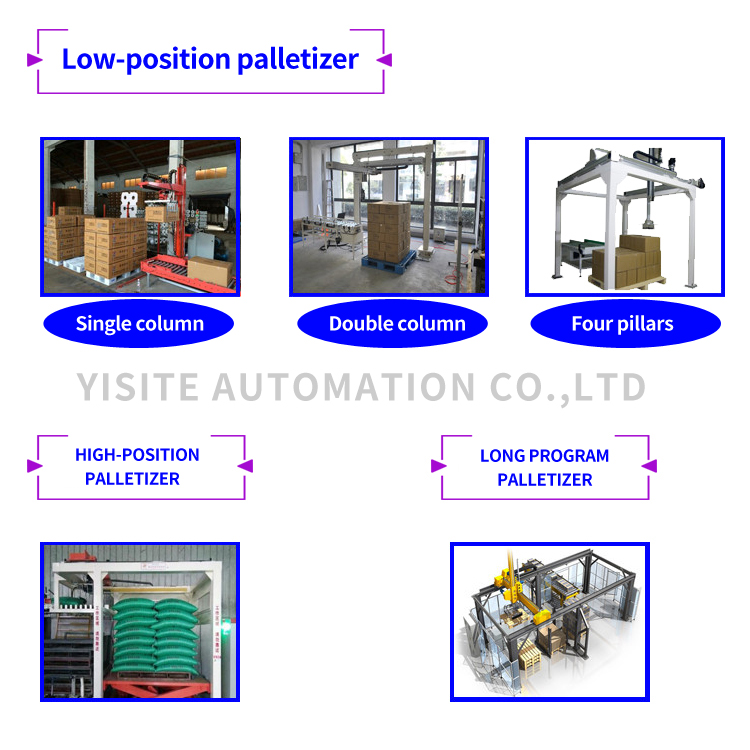

Products

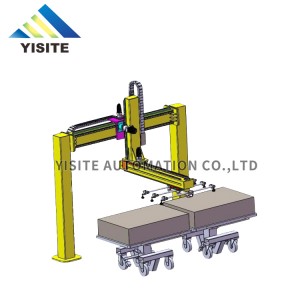

Single column intelligence 3 axis servo automatic stacking packing manipulator for carton stacking

Carton stacking manipulator characteristics

1. Convenient control: PLC + display screen control, greatly facilitate the operation, management, reduce the production personnel and labor intensity, is an essential equipment for automated scale production.

2. Convenient operation: reduce the packaging cost, especially suitable for enterprises with small space and small output.

3. Non-driver operation: especially with the front and rear packaging machine, such as the front end with automatic unpacking, packing and sealing; the back end with automatic stack supply machine, sword packer, wrapping machine and other packaging equipment, to realize automatic unmanned packaging and storage.Right Angle type, solid structure, suitable for heavier goods.

Three-axis servo palletizing manipulator description

Packaged cartons are positioned by delivery to the designated palletizing area, The servo stacker positioned the extended arm and the suction cups directly above the carton positioning, When the carton positioning signal is issued, The cantilever is controlled downward (Z axial motion) by the servo motor, When the suction absorbable height is reached, The cantilever stops falling, Vacuum suction open, After sucking up the carton, Coverlever Seromotor reversal, After lifting the cantilever to a safety height, Movement of the cantilever through the left and right servo motor, Position the cantilever movement directly above the desired position (X-axis motion), (Z-axis movement) After positioning above, The cantilever rises down the servo motor starts moving, Move to set position (suction disc loose, Automate finding the height of the carton), Code the carton into the specified location.Repeat the above action, after the whole palletizing, the buzzer alarm, to remind that the palletizing has been completed.The porter takes away the stacked tray, puts it into the new tray, and reciprocates it.(The suction cup on the cantilever can also move the Y-axis through the servo motor, moving to the specified position, and the 3-axis can be moved at the same time.)

Product technical parameters

1)Machine size:L2400*W2200* H2800mm

2)clamp:gripper

3)stacking type:according to customers require

3)speed:6-7 carton/minute

4)weight:700Kg

5)Voltage:380V 50/60Hz

6)Air resource:0.6-0.8mpa

7)Material:carbon steel,plastic spray painting

8)PLC: Mitsubishi

9)servo :Mitsubishi

10)Pneumatic elements:SMC

11)photoelectric components:Omron

12)Carton size:L200-600*W150-500*H150-500mm