Products

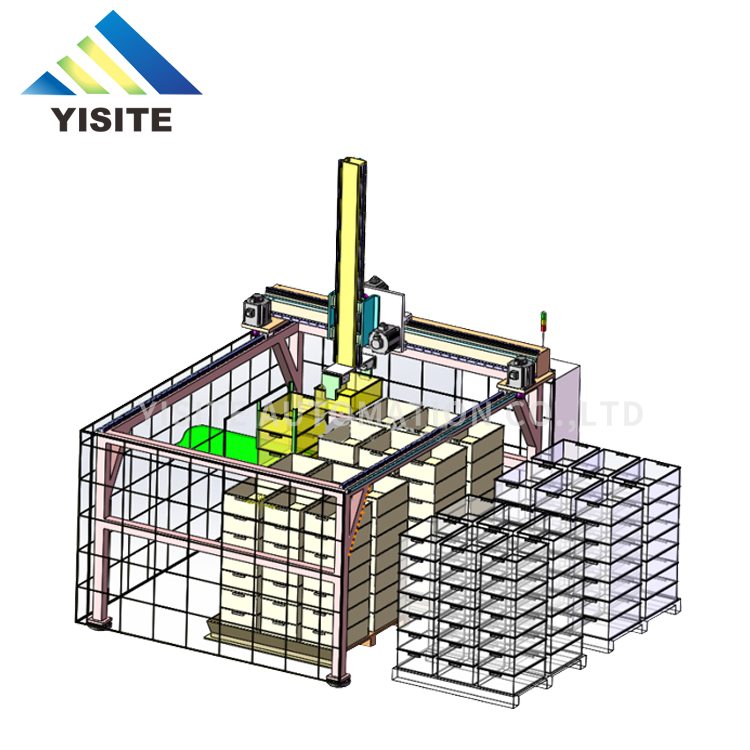

double pallet gantry palletizer

Characteristics of the gantry stacker

1. gantry stacking palletizer using touch screen operation to realize human-computer dialogue, which can show the production speed, fault cause and location, and has a high degree of automation.Using PLC, the number of sorted code layers, stack supply, and discharge can be controlled.

2. Equiped with imported elements, stable operation, reliable performance and strong durability.

3. Protective facilities are provided. When the cover door is opened, the machine operation auto-stop.

4. The adjustment of the stacking mode is convenient and simple, and can be carried out on the touch screen.

5. Several stacking ways can be completed without replacing the stacking parts.

6. Compatible with 2 trays, more efficient and faster

Technical parameters of fully automatic stacking palletizer

Technical parameters of fully automatic stacking palletizer:

Paltizing capacity: 5 boxes / min

Stacking height: 4 -6 layers

Power supply: 380V, 50 / 60HZ around 4KW

Gas source pressure: 6Kg / cm², approximately 400L / min

Mechanical size: L2550 * W1950 * H3200mm (depends on actual size)

PLC: Mitsubishi (Japan)

Photoelectric control: Omron (Japan)

The frequency converter: Mitsubishi (Japan)

Pneumatic elements: AirTac (Taiwan)

Equipment weight: approximately 2,000 k g

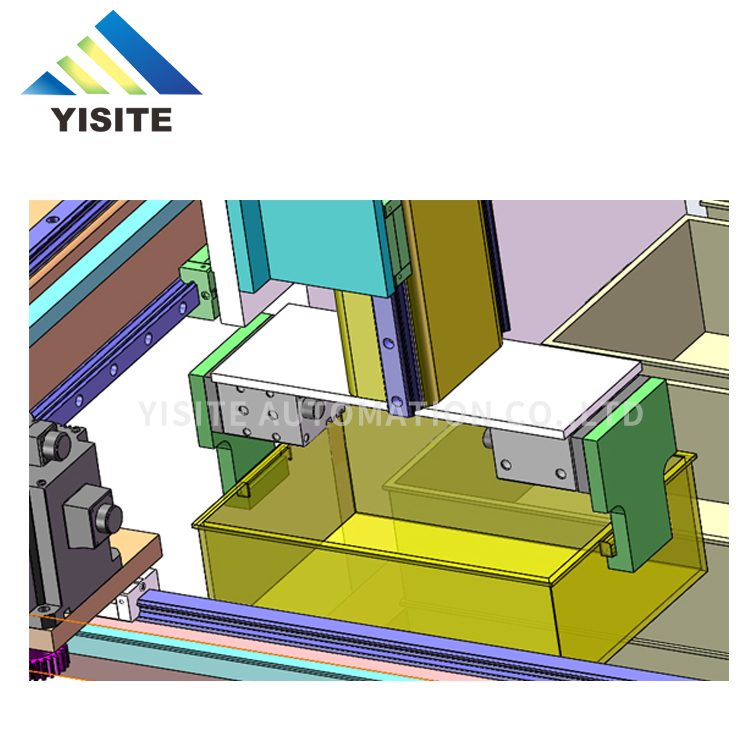

Stack section

The stack is manually placed to a designated position for easy palletizing.

stack board output device.The palletizing good stack plate is carried and output by the forklift truck.

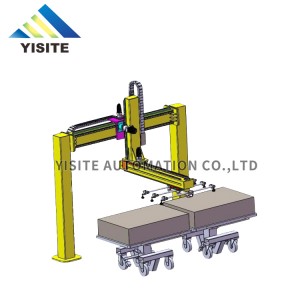

The robot palletizer can be integrated into any production line to provide intelligent, robotic and networked production sites. It can realize palletizing logistics for various operations in the beer, beverage and food industries. It is widely used in cartons, plastic boxes and bottles. Classes, bags, drums, film bags and filling products. It is equipped with three-in-one filling line, etc., and palletizes various types of bottles and bags. The automatic operation of the palletizing machine is divided into automatic feeding, transfer, sorting, stacking, stacking, lifting, feeding, stacking, and exiting.