Products

electric jib crane Robot Arm manipulator

Features of the cantilever suspension

1.Choose an aluminum alloy type arm or a steel cantilever;

2.Modular assembly, replaceable cantilever length;

3.Rotary angle of 0-360°;

4.Easy installation and fast.

Advantages of cantilever suspension

1. cantilever is a new generation of light lifting equipment for modern production. With high reliability of ring electric gourd chain is especially suitable for short distance, frequent use and intensive lifting operation, It has the advantages of high efficiency, energy saving, trouble saving, small area, easy operation and maintenance.

2. The cantilever is more flexible and wide adaptability, and is a necessary separate emergency lifting equipment on the efficient and automatic production line, which can ensure the smooth flow of the production line.

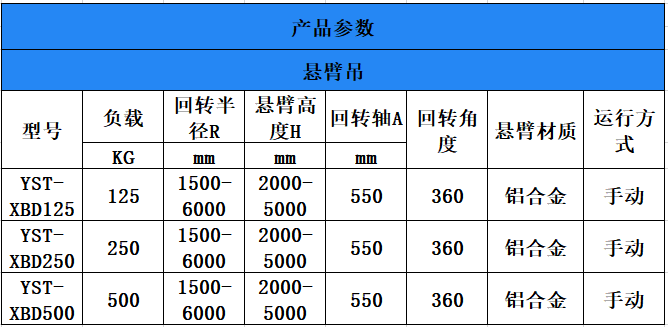

| Model | Load | R/mm | H/mm | A/mm | Rotation | Material | Working |

| YST-XBD125 | 125 | 1500-6000 | 2000-5000 | 550 | 360 | aluminium alloy | Hand |

| YST-XBD250 | 250 | 1500-6000 | 2000-5000 | 550 | 360 | aluminium alloy | Hand |

| YST-XBD500 | 500 | 1500-6000 | 2000-5000 | 550 | 360 | aluminium alloy | Hand |

Product Description

Collaborative robots are a form of robotic automation built to work safely alongside human workers in a shared, collaborative workspace. In most applications, a collaborative robot is responsible for repetitive, menial tasks while a human worker completes more complex and thought-intensive tasks. The accuracy, uptime and repeatability of collaborative robots is designed to complement the intelligence and problem-solving skills of a human worker.

Collaborative robot designs differ greatly from their industrial robot counterparts. Featuring rounded edges, force limitations, and light weights, collaborative robots are first and foremost designed for safety. Most collaborative robots are equipped with a series of sensors to avoid collisions with human workers, as well as safety protocols to shut down if any form of unplanned contact occurs.

Product Features

1.Choose an aluminum alloy type arm or a steel cantilever;

2.Modular assembly, replaceable cantilever length;

3.Rotary angle of 0-360°;

4.Easy installation and fast.