Products

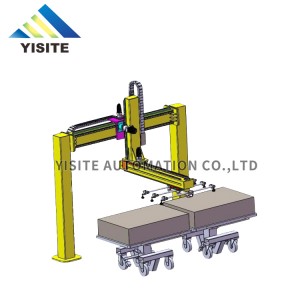

Carton stacker two column palletizer

Structural characteristics of the pallet stacker:

1. The full tray is equipped with the monitoring device and automatically adjust the production speed according to the monitoring data.

2. The structure of the tray stacker is simple and easy to maintain. The door of the control cabinet is equipped with a sealant strip and equipped with a high-quality ventilation and filter device.

3. The equipment is equipped with multi-layer alarm indicator, which can indicate different faults (faults to be reset, automatic reset fault, operation instructions, etc.).

4. When the box stack appears crooked, inverted, scattered can automatically stop.

Safety protection device can automatically stop and alarm in the abnormal operation of the equipment.

Product Details

A palletizer is an automated unit load forming machine used to stack and orient several individual products into a single load for a more convenient and labor save.

Packaging System included wrapping around cases , palletizer, robot palletizer, etc

Application industries

Automatic Robot Palletizer Machine use preemptive skills and controls. The optimized planning of professional skills team makes the palletizing compact, regular and beautiful. The rapid palletizing speed and stable function have become the choice of palletizing work for many companies.Usually the machine can automatically finish a series of work, such as flattening, slow stop, transposition, bag pushing, palletizing and so on.The Automatic Chemical Cement Bag Palletizer has the advantages of optimized construction planning and stable and reliable movement. The palletizing process is completely automatic, and there is no need for manual intervention in normal work, so it has a universal scope of application.