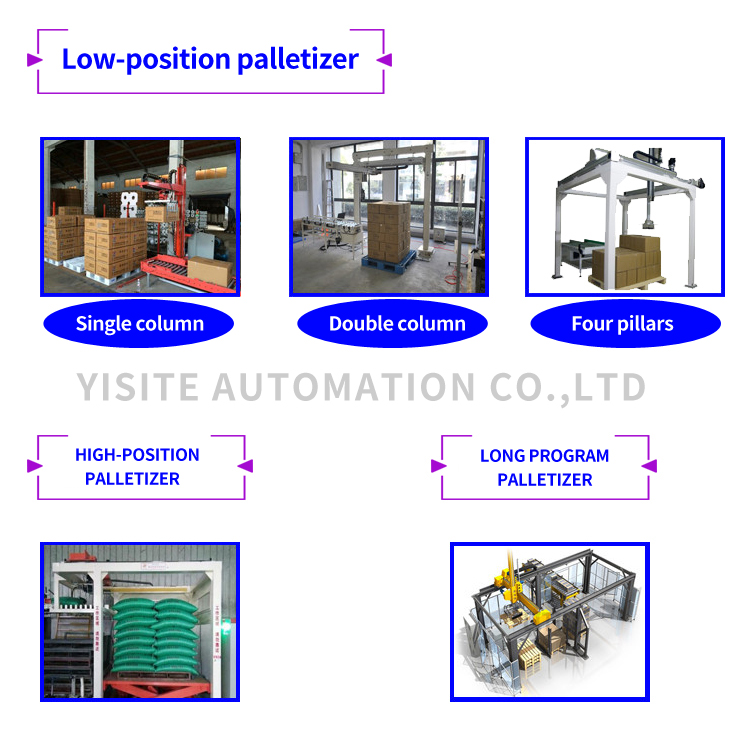

Products

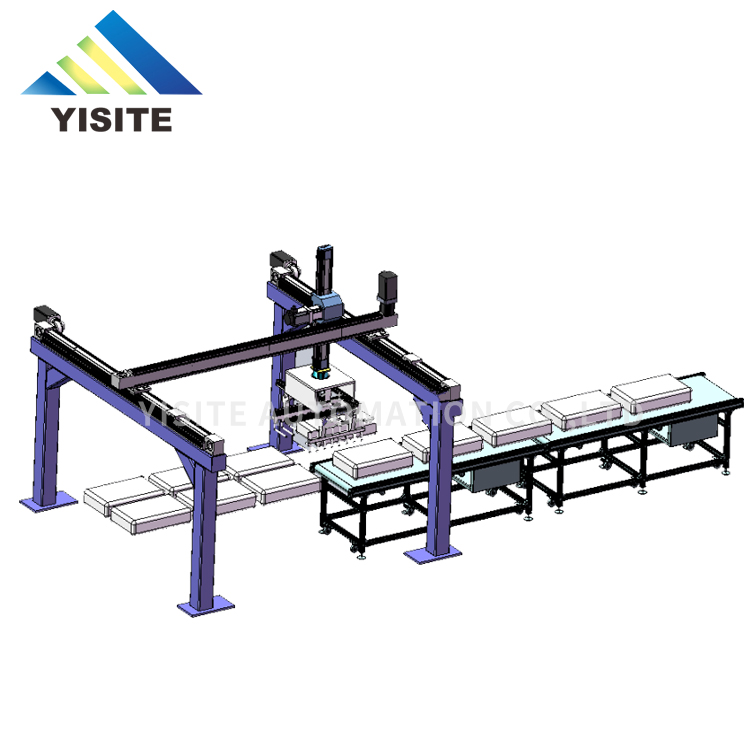

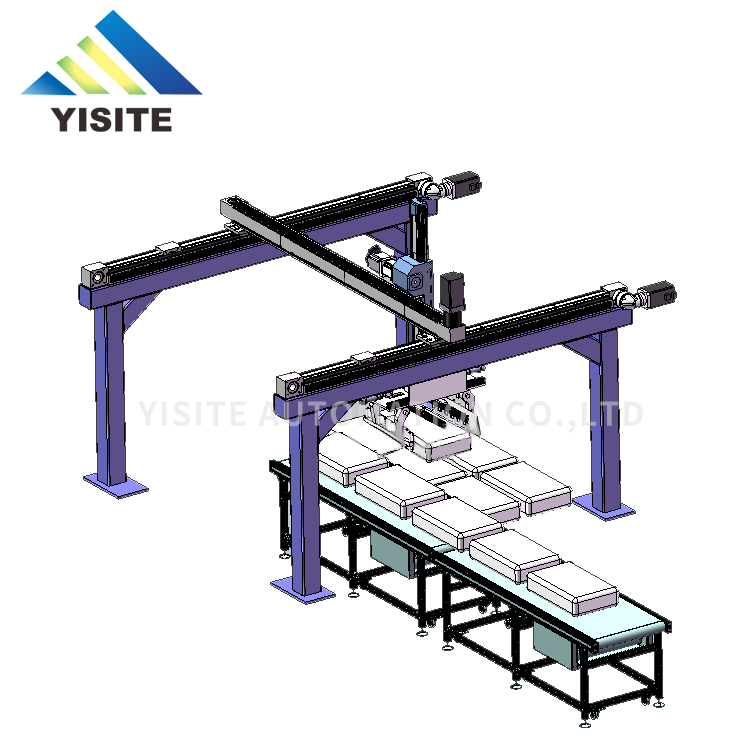

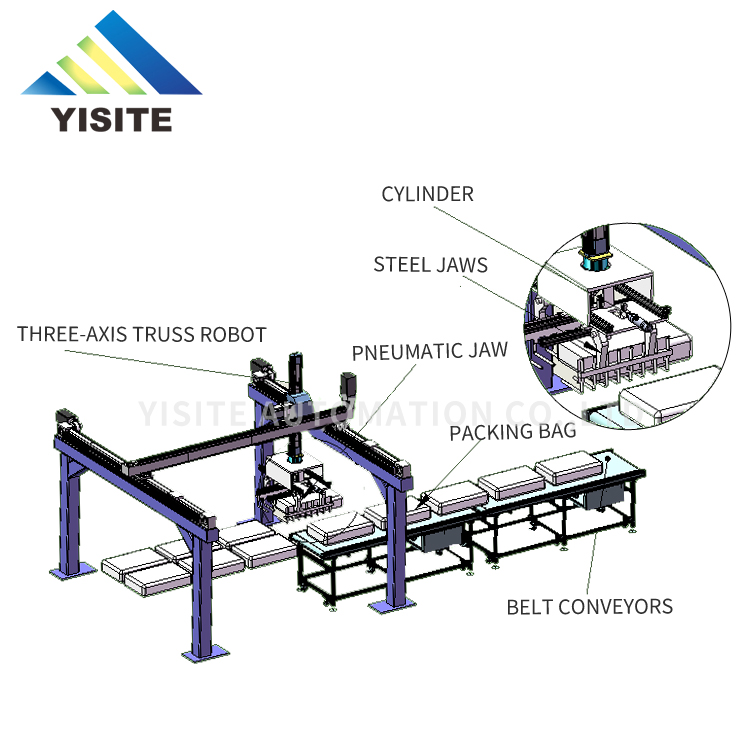

bags cartons automatic gantry palletizer

Packing bag fully automatic truss handling palletizing manipulator

Automatic palletizing function will neatly and automatically stacking (or dismantle) on the tray (or production line, etc.) of different shape and size of the packaging.In order to make full use of the area of the tray and the stability of material stacking, the robot has material stack order and arrangement setting device.It can meet from low speed to high speed, from bag packaging to carton, from palletizing a product to a variety of different products.Applied to product handling, palletizing and etc.it’s widely used in chemical industry, plastic, building materials, medicine, food, battery materials and other different fields.

ents, stable operation, reliable performance and strong durability.

3. Protective facilities are provided. When the cover door is opened, the machine operation auto-stop.

4. The adjustment of the stacking mode is convenient and simple, and can be carried out on the touch screen.

5. Several stacking ways can be completed without replacing the stacking parts.

6. Compatible with 2 trays, more efficient and faster

Advantages of automatic palletizing manipulator

1. Simple and flexible: bag packaging and handling palletizing robot is composed of mobile transport and bag packaging palletizing manipulator, palletizing robot has the advantages of simple, flexible, small power, energy saving, low cost and etc advantages;

2.Labor saving and improve efficiency: the palletizing handling robot can complete the grasping, handling, stacking of bags and packaging products, which can greatly save labor costs and improve the work efficiency of enterprises;

3. Fast speed and neat stacking: bag automatic packaging stacking equipment can carry out automatic stacking operation of various packaging bags, with the characteristics of fast stacking speed, neat stacking and high automation level;

4. Low fault rate, easy to maintain and maintenance: bag packaging automatic mechanical stacker structure is very simple, so the failure rate is low, easy to maintain and repair.Less main components, less accessories, low maintenance cost;

5. Simple and convenient operation: the bag packaging automatic stacker can be set in a narrow space, and effectively moved to the designated position according to the track set by the user. All the control can be operated on the control cabinet screen, and the operation is simple;

6. Versatility function: the paltizing and stacking of different goods can be completed by replacing the clam grab of the manipulator, so that reduces the cost;

7. High work efficiency: the advantages of handling stacker manipulator is could be operated 24/7 , greatly improve the work efficiency and quality,to achieve the goal of reducing consumption and increasing efficiency;