Products

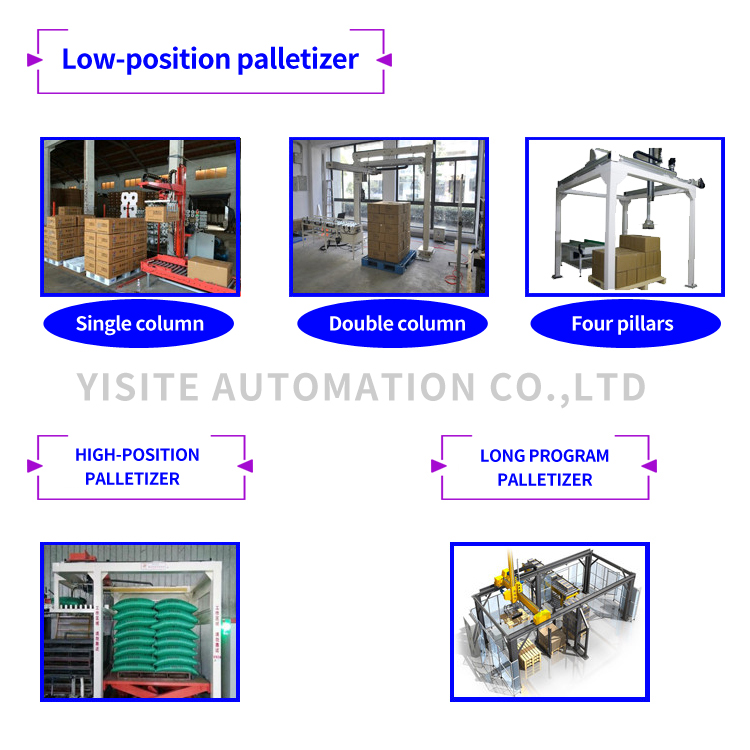

automatically stacking truss palletizer

Advantages of a fully automatic palletizing manipulator

The ability of fully automatic mechanical palletizing machine is higher than ordinary mechanical palletizing and manpower.The structure is very simple, so the failure rate is low, easy to maintain and repair.The main components are less, less accessories, low maintenance cost.palletizing manipulator can be set in a narrow space, which can be effectively used.All the control can be operated on the control cabinet screen, the operation is very simple.Strong versatility: the stacking and stacking of different goods can be completed by replacing the starting point of the manipulator, to reduces the cost.

Application of manipulator stacker

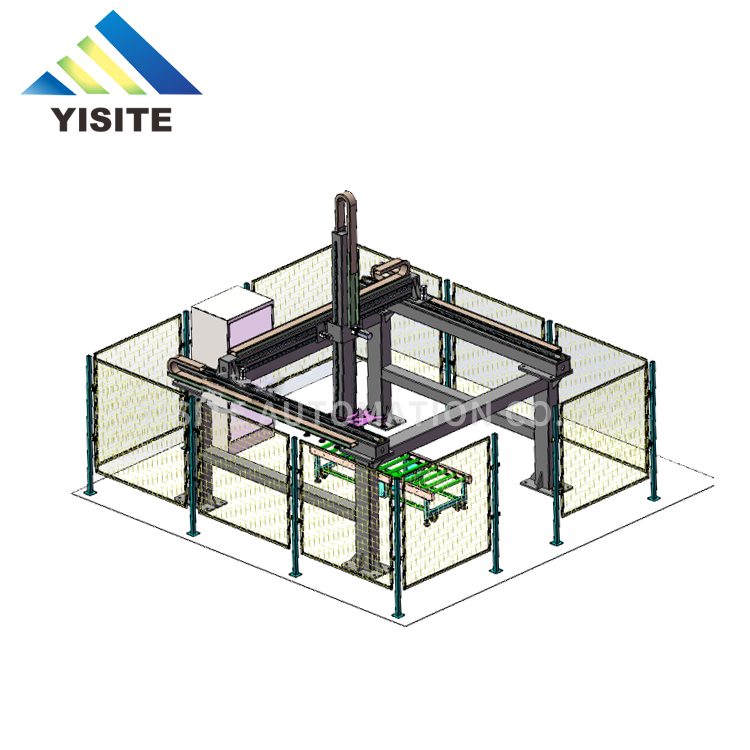

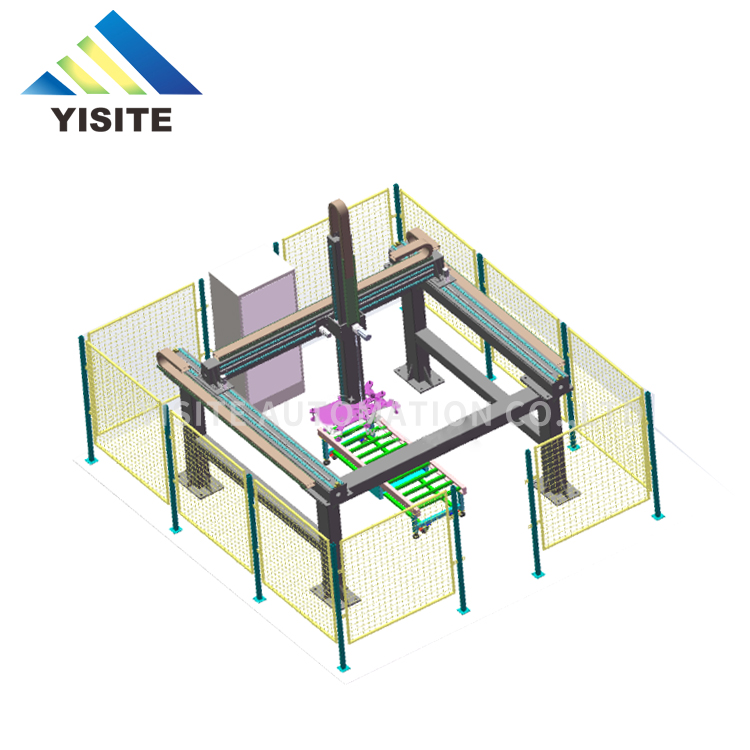

Handling stack manipulator can be integrated in any production line, provide intelligent, robot, network, can realize the beer, beverage, and a variety of food industry stacking, widely used in cartons, pharmaceutical chemical, beverage, food, beer, plastic, air conditioning, plastic boxes, bottles, bags, barrels, membrane packaging products and filling products and etc.With three-in-one filling line, all kinds of bottles and bags,the automatic operation of the stacker is divided into automatic box entry, box transfer, sorting, stacking, shifting, stacking, inlet support,stacking and other steps.

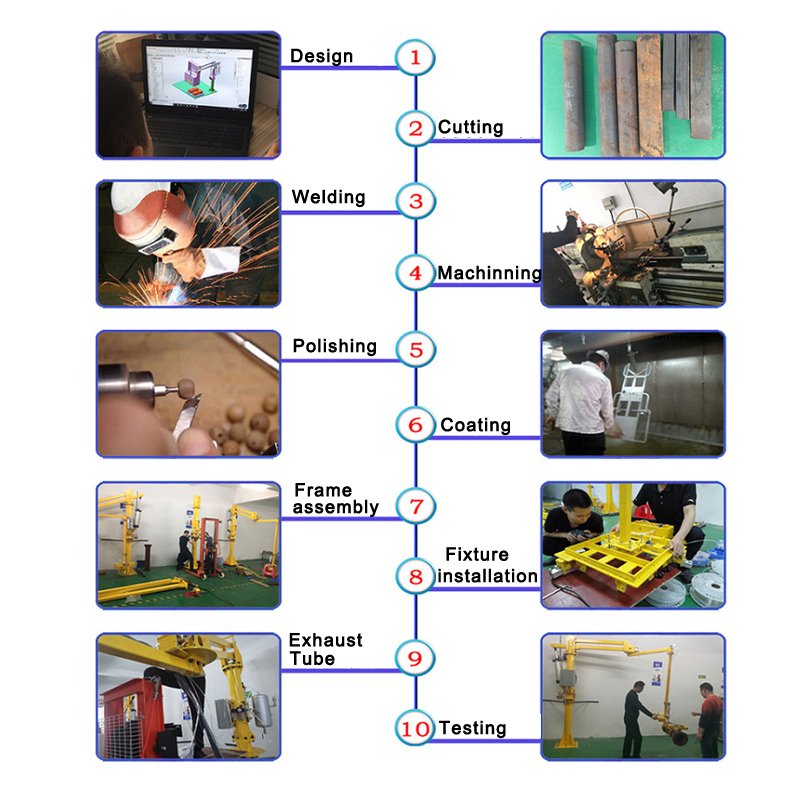

Workflow

Weighing and sealing bag →Conveying→flattened Bag→Conveying→Automatic stacking bag on the pallet→Taking out pallet with forklift