Products

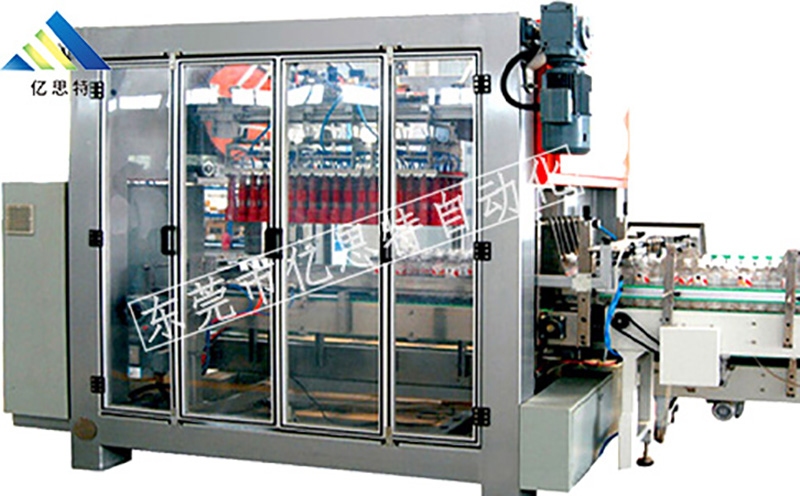

Automatic Cartoning Machine

Features of Automatic Cartoner

1、Reliable operation: This machine adopts special pneumatic components to achieve product selection and placement. Through mechanical operation, pneumatic and electrical control, it can accurately and reliably load products from bottle cabinets into cartons.

2、Smooth operation: The whole packing process is driven by inverter motor, which independently drives different mechanical mechanisms, translates and lowers the products, and it is automated with pneumatic, electrical, and lighting control. Coordinated movement, smooth and accurate movement. Box entry operation with manual box entry, automatic box entry and continuous fast box entry, etc.

3、 Grip operation is equipped with manual operation and automatic operation. With the advantages of safe operation, small footprint and large operating space. With a variety of protection functions, in case of failure in time. For example, if the bottles are not filled into the bottle belt and bottle transport platform, the bottles will automatically stop waiting; the machine will automatically shut down when the scratched bottles and cartons are put in the wrong place.

Advantages of Automatic Cartoner:

1、Adopt side feeding method: small footprint, simplify the transportation system of the former carton packaging machine, reduce the investment cost of the whole machine equipment.

2, three-stage decompression: the product has been fully decompressed to accurately align the product's buckle head, and the success rate of bottle gripping is 100%. After the product enters the packaging process, it is in the state of no pressure and stable transportation, which basically prevents the occurrence of the phenomenon inside the bottle.

3、Adopt German Igus linear positioning system: high positioning accuracy, precise movement, the machine can effectively reduce the shock and vibration of the equipment in the process of operation, greatly improve the stability and reliability of equipment operation. Lubrication-free, maintenance-free, good hygiene, long service life.

Application of automatic cartoner:

The automatic case packer can be used alone for various sizes of bottles, cans, tubs, combined with automatic packaging machine and filling machine to complete the downstream packaging line. It is widely used in pharmaceutical, food, daily use chemicals and other light industries.

The hard-arm power manipulator system mainly includes four parts

| Model | YST-HD-4007 |

| Capacity | 12000bph |

| Capability | 20 bpm |

| Power Supply | 220V |

| Power | 5.9KW |

| Air Pressure | 0.4-0.6Mpa,30L/MIN |

| Tape Size | 2 inch (48mm), 3 inch (60-72mm), length: 1000mm yard |

| Machine Dimension | 2200(L)*1880(W)*3000(H)mm |

| Weight | 2200Kg |

| Package Type | Film + Carton + Wooden Case |

| Suitable Products | Glass Bottle/Pet Bottle/Pet Bottle/Tinplate Can |

| Gripper Type | Airbag suction cup / Mechanical grip / Sponge suction cup |