Products

Rigid arm fixture air Balancer Manipulator

characteristic

Working length:700-3200mm

Lifting height:800mm

Rotation:360°

Max weight:300kg,(customized is available)

Air pressure:0.6-0.8MPA

High stability and easy to operate

Using the principle of pneumatic pressurization, the workpiece operation is only needed to operate the control button.

High efficiency and short treatment cycle.When loading, the operator can control the artifact movement in space with a smaller power, and can stop at any position, the operation process is simple, fast, and consistent.

High safety performance,Air cut-off protection and automatic braking device.

The main components of international famous brands are all international famous brands, and the quality is guaranteed.

The hard-arm power manipulator system mainly includes four parts

1) Track rails system;

2) Machinist host machine;

3) Fixture part;

4) carry part;

5) Gas circuit control system.

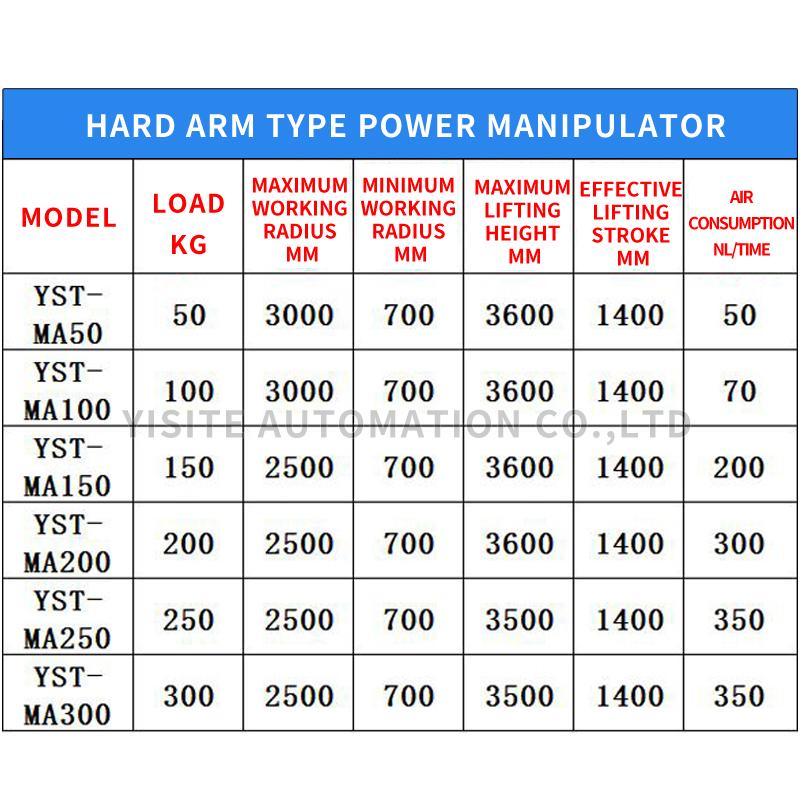

SPEC

Weight load:100kg

Max. Arm Length:1.5m

Grasping:suction or clamp

1. When the torque is generated, the workparts flipped or inclined, and the plant height is limited.

2. The whole process is "floating", which greatly reduces the power consumption of workers' handling workparts.

3. Equipped with a brake device to effectively lock the rotary joint to prevent drift.

4. Gas break protection and alarm, self-lock to prevent falling when air pressure drops.

5. Parts protection and control device to avoid accidental impact and dust accumulation, and ensure the stable operation of precision elements.

The system is equipped with a gas storage tank to provide continuous and stable compressed air for the system. When the main gas supply source accidentally breaks off the gas, it can provide a certain period of time, and make the system have sufficient power to complete the operation or unload the workparts.

Equipped with safety misoperation protection device to prevent damage to person or equipment. Before the operator confirms the installation condition,the workparts are not installed,the workparts shall not be unloaded.The artifact must be effectively supported to be released.

with a safety control system. During operation, the system will not suddenly change the load or no-load pressure due to mis-operation, so the manipulator will not quickly rise or fall and cause harm to people, equipment or products.

The brakes are located at the connecting joint to prevent the manipulator from rotation and loosening, and can also make it easy for the operator to control the workpiece, so that the mechanical arm and fixture can stop at any position.

The automatic sensor can be installed on the operation handle, which is automatically locked when the operator leaves the operation handle, and the brake can also be used to park the manipulator after work.When the brakes are in the brake state, all the buttons in the mechanical arm do not work to prevent accidental damage.

A stop valve function is designed to prevent the clamp from not releasing the object unless instructed by the operator.

Product Overview

Handling manipulator, stacking manipulator, loading and unloading manipulator, auxiliary assembly manipulator, material turnover manipulator,automatic handling manipulator, automatic stacking line.

Product Description

Rolls of paper or foil can be lifted, turned and revolved with an grippers. A single operator can handle rolls weighing up to 350 kg.

Product Advantage

1) Break gas protection device

2) Misoperation protection device

3) Brake device

4) Load-bearing limit protection device

5) Low-voltage alarm device (optional)

6) Anti-rebound technology

7) Explosion-proof.